Q: How much does a car turntable cost?

A: Car turntables usually start at around $12,750 depending on the specifications and size.

Q: What does this price include?

A: This price includes all turntable components, pit ring, all necessary drawings and schematics, crating and packaging ready for shipping. Shipping costs are additional.

Q: What about pit construction costs?

A: Pit construction will be an additional local expense between the turntable owner and his contractor.

Q: What sizes of turntable are available?

A: Diameters can start as little as 14ft and range thru 25ft depending on type of vehicle use.

Q: What types of turntable are available?

A: Car turntables can be either air bearing powered or electro-mechanical powered.

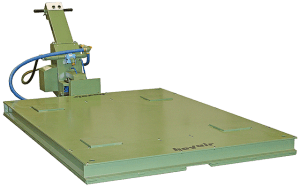

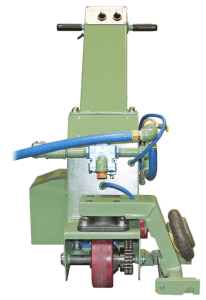

Q: How do electro-mechanical turntables work?

A: Electro-mechanical turntables are constructed to rotate using a single inner ring bearing and pit mounted floor raceway. A central pivot drive assembly is activated by the system’s hydraulic motor drive unit, which causes the turntable to rotate smoothly on the installed raceway. Compressor is not necessary.

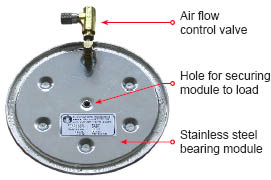

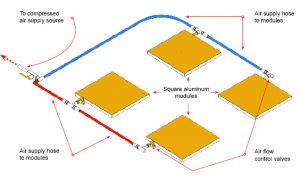

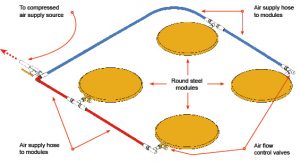

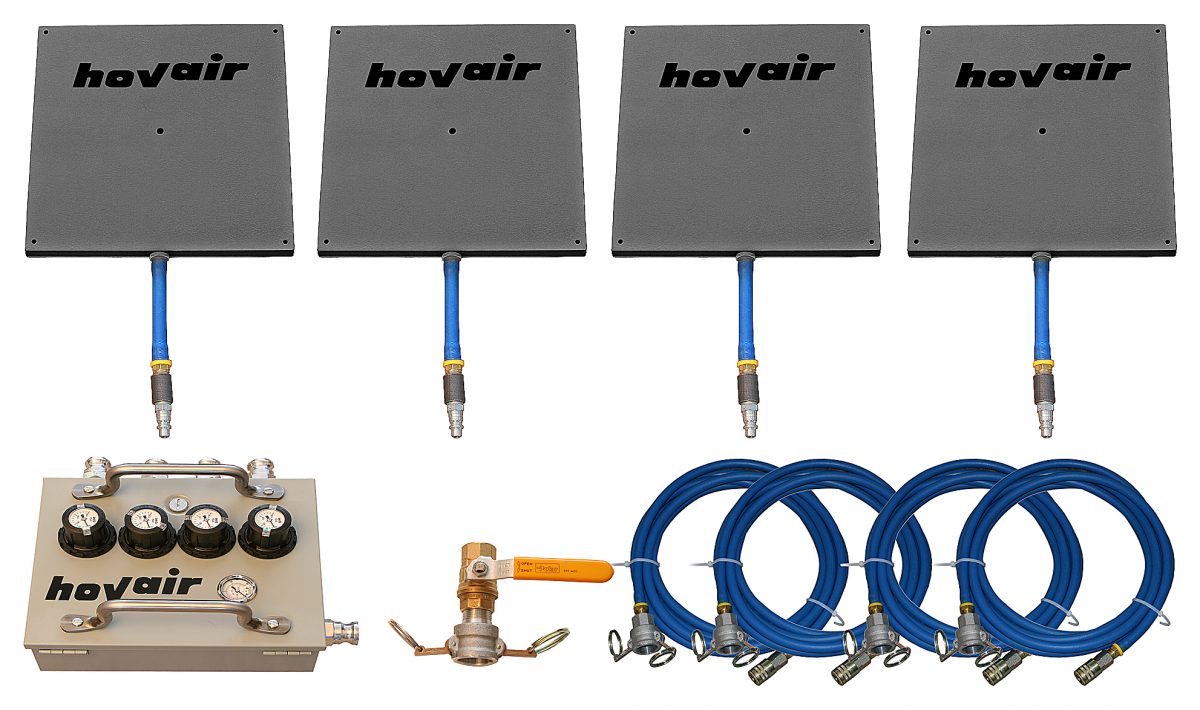

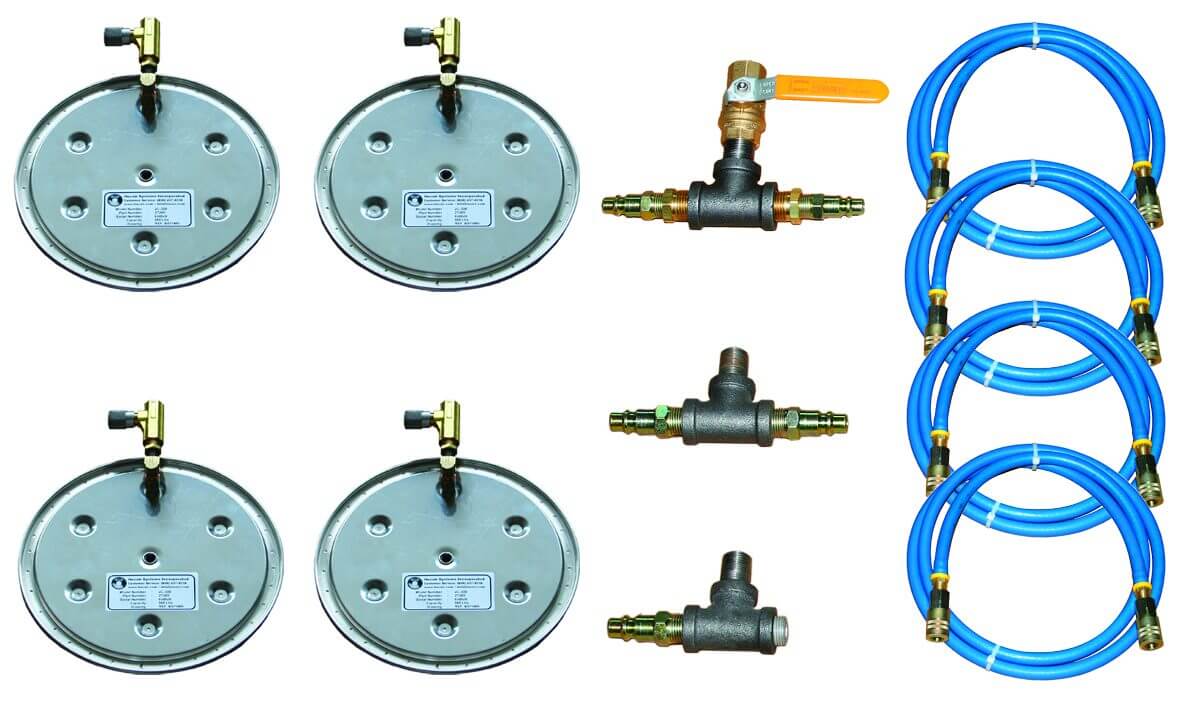

Q: How do air powered turntables work?

A: Air powered turntables require an air compressor to be installed at a reasonable proximity to the turntable. Air supply lines are fed from the compressor to the turntable manifolds, through which, air is allowed to flow to each individual onboard air bearing. When the turntable is activated, the air bearings rise to lift the turntable away from its base unit. From this point a drive wheel rotates the turntable as programmed. When rotation is stopped, the air bearings deflate and the turntable lowers back to it resting place.

Q: Will I need to dig up my garage floor or driveway?

A: Unfortunately, yes. Your turntable needs to be fitted correctly for it to give you many years of reliable service. Whether you purchase an air bearing or electro mechanical powered turntable, you will need to construct a suitable pit to house the turntable. A typical pit will vary between between 5 inches and 10 inches deep.

Q: How will I know the turntable pit dimensions, and what goes where?

A: Every Hovair Systems turntable is supplied complete with detailed operator manual and all the necessary drawings to assist you and your contractor to construct the pit correctly.

Q: What does a typical turntable pit construction project consist of?

A: A typical pit consists of digging out a circular pit to the depth as indicated on the supplied pit construction drawing. Depending on the type of turntable being installed, it may be necessary to also construct a small drive unit pit alongside the turntable pit. Concrete is then poured into the pit and leveled to the specifications in the supplied pit drawing. A sectional pit ring assembly is shipped before construction begins, and when the first concrete pour is complete, the sections of the pit ring are fitted to the pit to form its circumference. Pit ring sections are then correctly leveled and secured with a final pour of concrete. Finally, a mounting plate is then fitted to the center of the pit to interface with the system’s center pivot assembly. Detailed drawings are provided for pit construction.

Q: Can I install a turntable myself or do I need a contractor to do it?

A: Most installations are handled by a reliable and experienced contractor who knows how to read and correctly interpret the supplied drawings. However, if you have a good mechanical aptitude and can read and understand drawings, then it might be possible to do this yourself. We would recommend talking to a contractor to ascertain all details of the project before undertaking any work.

Q: Does Hovair Systems have an installation service?

A: Yes, we do, but we do not undertake pit construction work. If you are able to have your turntable pit constructed by a local contractor, Hovair Systems would be happy to quote you a price for the turntable installation.

Q: Will you talk to or work with my contractor?

A: Yes, absolutely. We often liaise with contractors installing our turntables and give them as much help and advice as possible. Our support service is second-to-none and we help in any way we can.

Q: How does the turntable arrive at my location?

A: Your turntable will have been pre-assembled and tested for correct operation at our factory before being shipped. All turntables are sectional so they are easily taken apart for shipping. Many of the sectional parts will be number or color coded making assembly an easy task. The pit ring assembly will be shipped separately ahead of time to allow you to get it installed into the pit before the turntable arrives. The remainder of the turntable will be packed into manageable size crates.

Q: How is the turntable assembled?

A: All Hovair Systems turntables are accompanied by a comprehensive, easy-to-understand operator manual which includes full color diagrams and pictures that illustrate various stages of the assembly. It is not rocket science and most components fall into place quite easily.

Q: Where do I get a compressor?

A: We can supply a suitable compressor as part of your turntable order. We can advise you on the right compressor for your needs at the time of order.

Q: What about spare parts for turntables?

A: No problem. We always use brand name and good quality components when designing our turntables. Spare parts are rarely a problem and we normally have them in stock for immediate shipping.

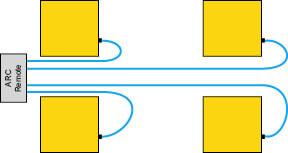

Q: I have two vehicles and they have different parking places in my garage. Can you help with this?

A: Absolutely. All car turntables can be supplied with garage-door-style clickers that can be kept in each vehicle. Your turntable can be programmed so that the first clicker action of either clicker will cause the turntable to stop at a certain point, and a second clicker action will cause the turntable to continue rotating to a second preset point. This will allow each vehicle to drive off the turntable at its correct preset angle and location.