Air Bearing Systems are assembled by using three or more air caster load modules to suit

the size and shape of the loads that need to be moved. The flexibility of these air bearing systems means that load modules can be used at various points under a load, not necessarily at the corner points. This is particularly important for odd shaped loads that might have various areas that need support, or that have disproportionate weight distribution.

We have air bearing and air caster systems that can lift loads as light as 500 pounds and range through to 100 tons and beyond.

A standard single 12-inch air bearing is capable of lifting around 1000 pounds (½ ton) on its

own. When used in a normal system of four linked caster modules this capacity is raised to 4000 pounds (2 tons).

A heavy duty 48-inch air bearing can easily lift 30 tons on its own, so when coupled with a system of four,

it will increase to a lifting capacity of over 120 tons.

By using sets of different air bearing sizes and air pressures, we are able to supply systems than can easily lift over 200 tons and more.

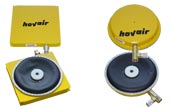

repetitive movements of a single load – perhaps large heavy machine moving – the modules can be permanently housed beneath the load until it needs to be moved again. For this, we recommend the round steel modules with A-type bearings on board. This is achieved by attaching the modules, via a mounting plate, to the load. The fundamentals of this type of attachment are: move it, drop it and forget it. Thereafter it is a simple case of snapping on an air line hose and it’s instant load movement again. In the picture above is a typical 4-station round steel air bearing system fitted with A-type air bearings.

The square aluminum systems are considerably lighter than the round steel systems, and are usually used in conjunction with a

remote control unit. The round steel systems are more inclined to be used in the “move it and forget it” mode, whereby they are permanently fixed to the load by way of a mounting plate and are instantly available when the load needs to be moved. The square aluminum type is ideal for when loads can be placed directly onto the modules, or when areas of the load can be lifted to allow a module to be placed underneath it. In the picture above is a typical square aluminum system with remote control, and fitted with A-type air bearings.

Low profile air bearing systems are especially suitable for loads that need to be lifted vertically away from their base, or floor, before floating them off to their destination. Depending on the type of air bearings used, a low profile system can lift the load vertically as much as 3 inches. Low profile air bearing systems consist of thin aluminum caster modules with B-type high-lift bearings on board. Clearance for these modules can be as low as 1½ inches making them suitable for sliding under loads and machinery that have low clearance heights. All low profile systems come complete with remote control. In the picture above is a typical aluminum low profile kit system complete with all hoses and fittings.

VL-type air bearing systems are especially suited to more lightweight loads ranging from around 500 to 2000 pounds. They provide the ideal solution for clean room applications and for moving around delicate machinery in a safe and efficient manner. Loads can be placed directly onto these systems, although we do recommend using a mounting bolt (discussed at time of order) to attach them permanently to the machine. Once attached, these stainless steel caster modules can move the same load any amount

of times with comparative ease. In the picture above is a typical VL-type air bearing system complete with all valves, hoses and components to enable you to be up and running in not time at all.